Wireless Solder Iron (Wi-Ron) - Capstone Project

65 W Cordless Soldering Iron — USB-C PD — Lithium Battery System

Wi-Ron is a fully wireless, battery-powered soldering iron designed to deliver bench-level performance without a tethered power source. The system supports up to 65 W of tip power, heats from ambient to operating temperature in under 20 seconds, and maintains closed-loop temperature regulation using an integrated thermocouple tip. Power is supplied by an internal multi-cell lithium-ion pack with full protection circuitry and USB-C Power Delivery charging, enabling both portable operation and fast recharge. An onboard MCU with RTOS firmware manages temperature control, motion-based sleep, and a compact OLED user interface for precise, repeatable soldering.

This project reached the prototype stage, with all major subsystems designed and validated, but was not fully integrated or production-ready. It began as a personal project and was later expanded into a Capstone effort with a small student team.

Ethan Johnston – Technical Project Manager, Tip Circuitry and Firmware Designer, Mechanical and Industrial Designer. Zach Henderson – User Experience Designer. Owen Stuttard – Power Electronics Designer and Safety Officer. Brian Peters – Software and Firmware Lead

The Design

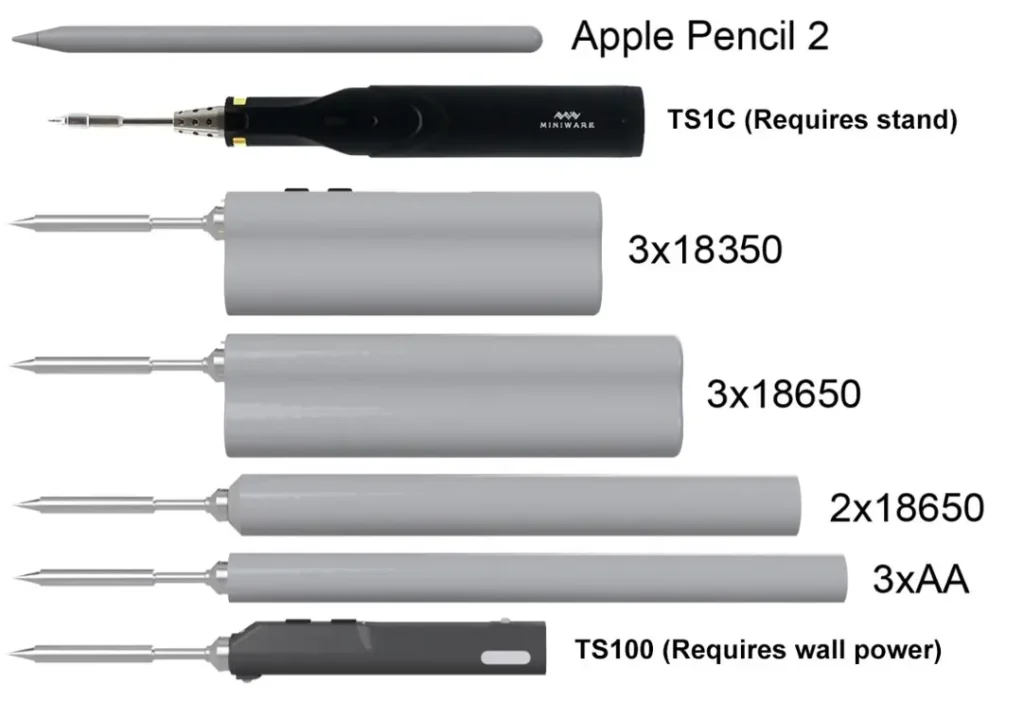

The ergonomics of the iron were shaped by the limits of current battery energy density, requiring tradeoffs between size, weight, and runtime. Early cylindrical designs using larger cells proved too long and bulky, leading to a shift toward a compact, peanut-shaped form factor. Adopting a 3S configuration with smaller 18350 cells significantly reduced size and weight while maintaining usability.

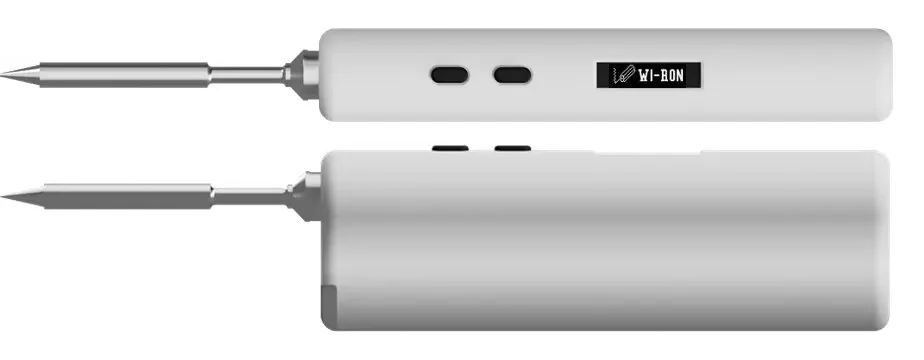

The final form provides a natural grip, space for internal electronics, and balanced weight distribution. The user interface is positioned on top for ambidextrous use, with the USB-C port and status LED at the rear and the tip and charging interface at the front, resulting in a practical and ergonomic layout.

System Architecture

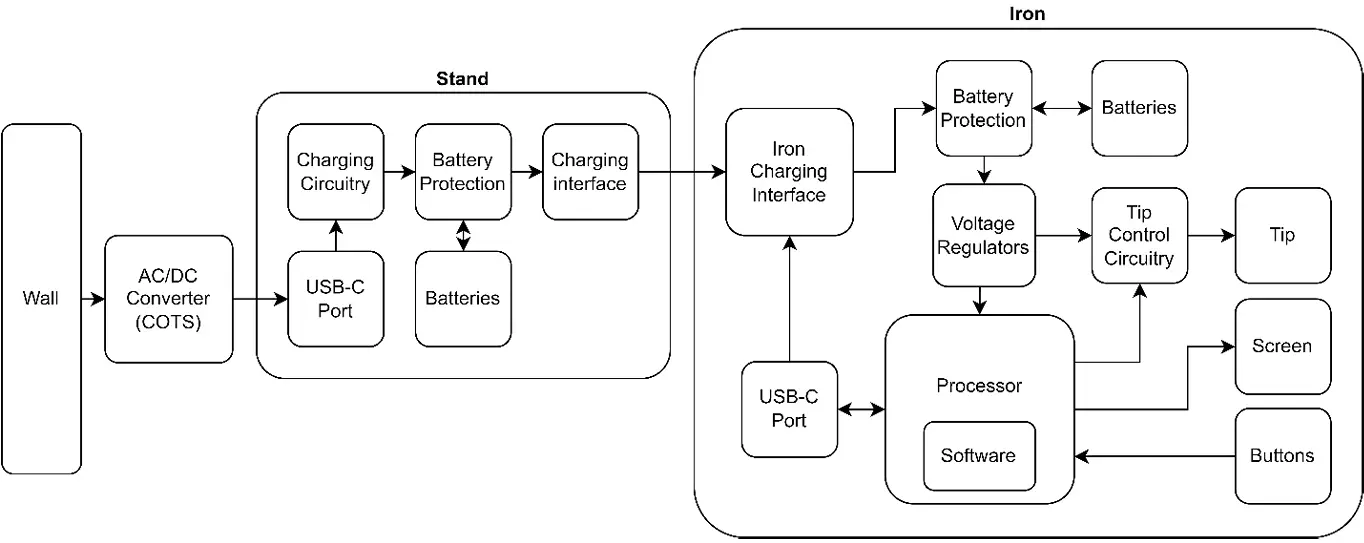

The system consists of two primary components: a portable soldering iron and a companion charging stand, both equipped with internal batteries. The stand is powered from a standard wall adapter and manages charging for both its own battery and the iron through an integrated, protected charging interface. The iron can also be charged directly via USB-C and uses onboard regulation to supply the processor and high-power tip control circuitry. A microcontroller running an RTOS coordinates temperature regulation, power management, and the user interface, which includes a display and two input buttons.

The iron is designed to operate independently for approximately 30 to 60 minutes of active soldering and is automatically topped up whenever it is placed on the stand, extending the effective runtime to beyond a full workday.

The stand doubles as a storage and transport case, holding the iron, interchangeable tips, and essential accessories, while incorporating its own battery system to extend overall runtime. A flip-out charging stand allows the iron to recharge during brief pauses in use, and the iron can also charge while fully stowed inside the case, enabling extended, uninterrupted workflows without a continuous wall power connection

Tip Control

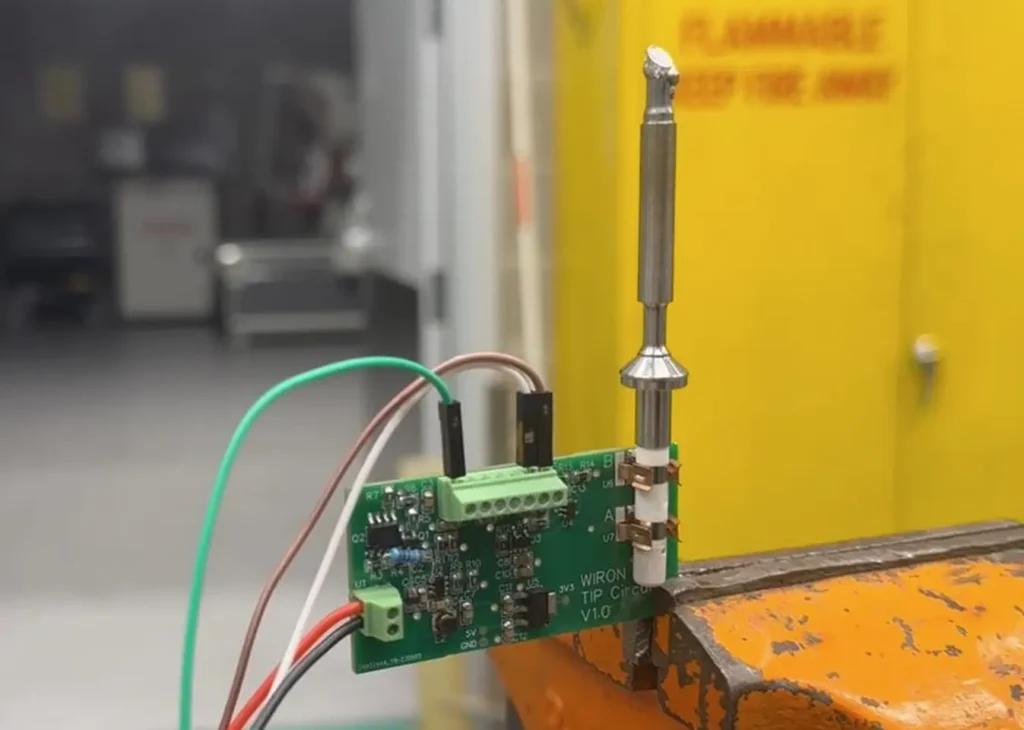

The tip control subsystem is responsible for measuring and regulating the soldering iron tip temperature, which is the core function of the system. The iron uses a standard cartridge tip with an integrated heater and modified N-type thermocouple, allowing temperature measurement via the Seebeck effect while delivering up to 65 W of heating power. A dedicated tip control board amplifies the thermocouple signal for ADC measurement, drives the heater through a PWM-controlled MOSFET, and provides regulated, low-noise supply rails for accurate sensing.

Temperature regulation is implemented in firmware using a closed-loop control system. Testing showed that variable-frequency PWM provided the greatest impact on heat-up performance, leading to the adoption of a proportional-integral control loop to eliminate steady-state temperature error. The controller alternates between heating and temperature sampling to account for the shared heater and sensor path, enabling stable and responsive temperature control across varying thermal loads.

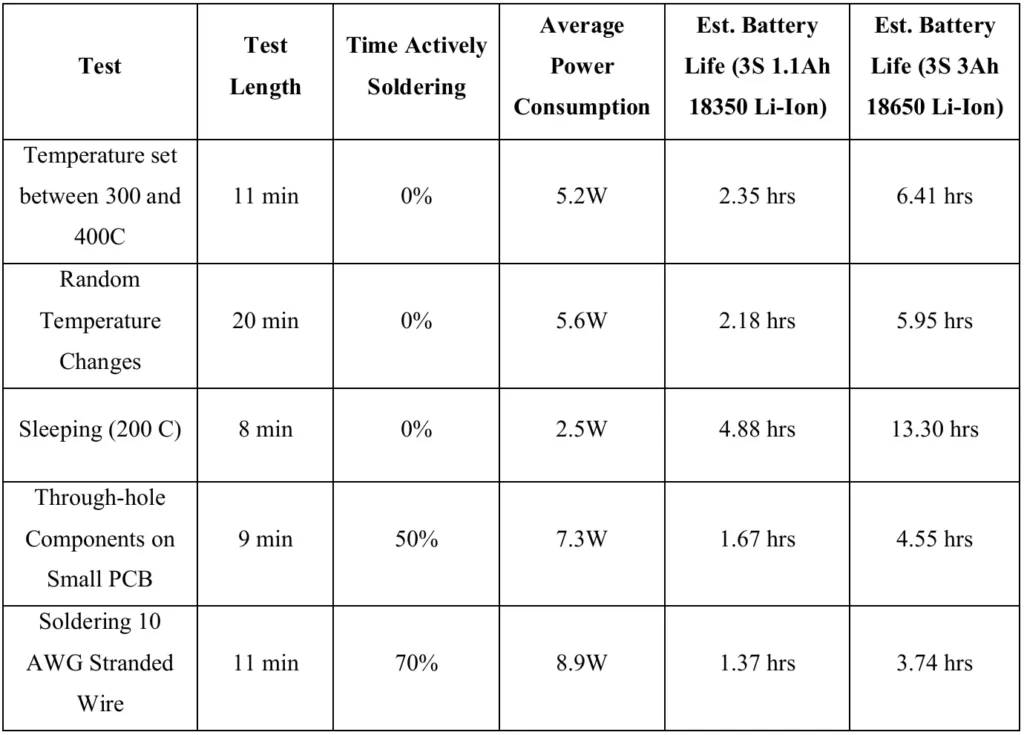

Runtime Analysis

Power consumption testing was conducted using a custom monitoring board to measure voltage, current, and power under realistic soldering conditions. All tests were performed using the same soldering tip, mounted in a TS100 soldering iron, to ensure consistent and repeatable results. The measurements showed an average power draw of approximately 8 W during typical use, increasing under heavier thermal loads, and were used to guide battery sizing and runtime estimates while balancing size and weight constraints.

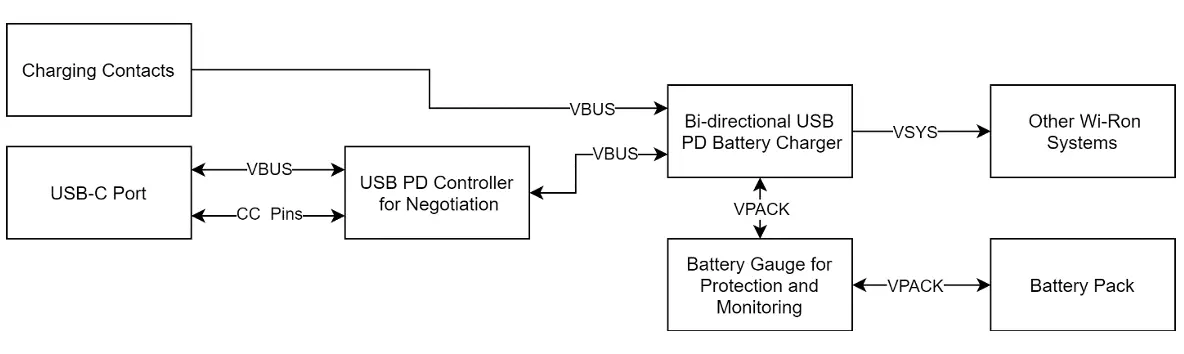

Power System

The power system is designed to enable fully cordless operation using an internal lithium-ion battery pack with integrated charging, protection, and regulation circuitry. USB-C Power Delivery was selected to maximize compatibility with common chargers, requiring support for voltage and current negotiation across a 5 V to 20 V input range. The charging architecture was modeled after laptop power systems to handle similar power levels while supporting safe and efficient charging.

The design prioritizes fast and reliable operation through cell balancing, comprehensive battery protection, and continuous monitoring. Protection features include overvoltage, undervoltage, and short-circuit safeguards, while state-of-charge and temperature monitoring provide user feedback and enable automatic shutdown in fault or overtemperature conditions.

Battery Pack

The battery pack design was driven by tight size constraints and the need to support high power draw while maintaining practical runtime. Power consumption testing indicated that a 3-cell lithium-ion configuration was required to deliver up to 65 W at the tip while achieving over an hour of runtime. A 3S pack provides a nominal 10.8 V, which is boosted to the 24 V required by the heater with high efficiency.

Cell size and charging performance were carefully balanced against weight and form factor. Smaller 18350 cells were selected over larger 18650 options to reduce size and mass, with the tradeoff of lower capacity. To offset this, power-saving strategies were implemented, including motion-based sleep using an accelerometer and automatic shutdown after extended inactivity. Additional battery disconnect circuitry allows the pack to be electrically isolated when the iron is off, improving safety and reducing standby power consumption.

The power system was the most novel and complex part of the design, combining lithium-ion batteries, USB-C Power Delivery, charging, and protection circuitry in a compact form. Limited reference designs required extensive research, iteration, and careful component selection, leading to multiple design revisions. Despite this complexity, the final architecture was informed by strong vendor documentation and reflects a well-considered and robust solution.

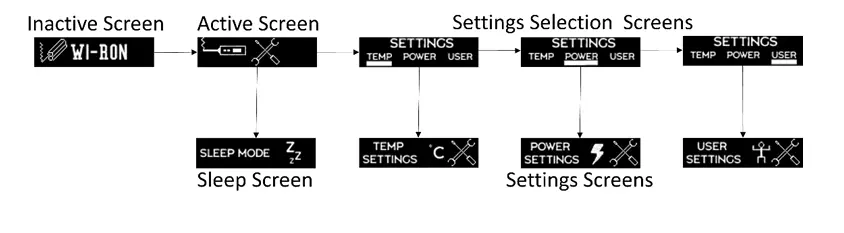

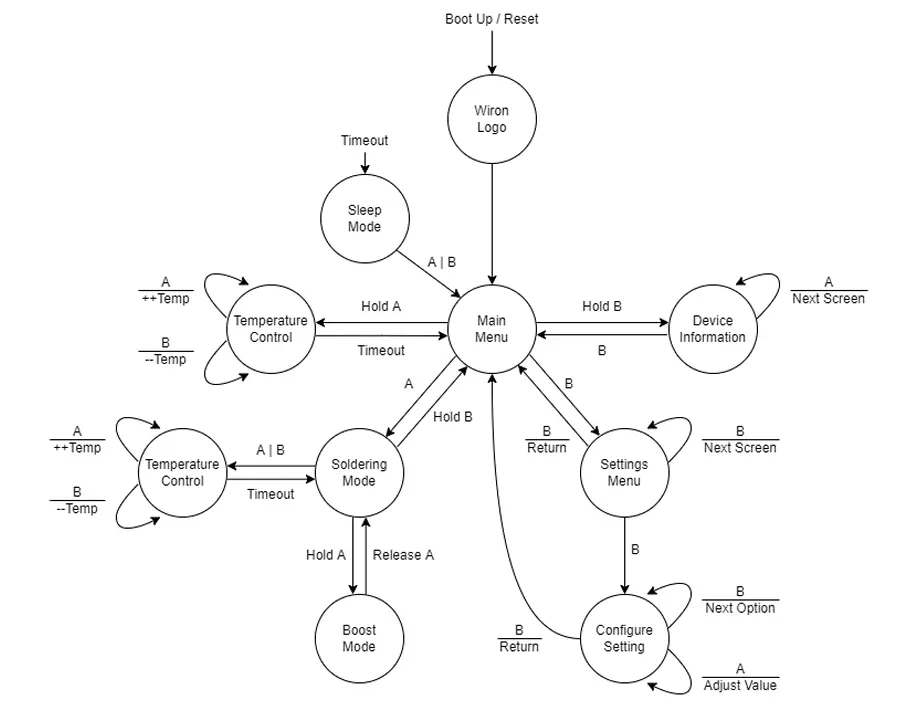

User Interface

The user interface was designed to fit within the compact form factor of the soldering iron while remaining intuitive and functional. It consists of two buttons, a small OLED display, and a status LED, allowing users to view and adjust settings such as temperature and power through multiple 128×32 pixel screens. Navigation is handled through a combination of short presses, long presses, and dual-button inputs, organized into a clear state-based menu structure.

Behind the interface, an accelerometer enables motion-based sleep functionality to reduce power consumption and improve safety, while an LED driver controls an RGBW status LED to indicate operating states such as heating, cooling, charging, and fully charged. Development was carried out in parallel through firmware prototyping on breadboards and the design of a dedicated interface PCB, with careful attention paid to voltage constraints, component size, and system integration.

Competition

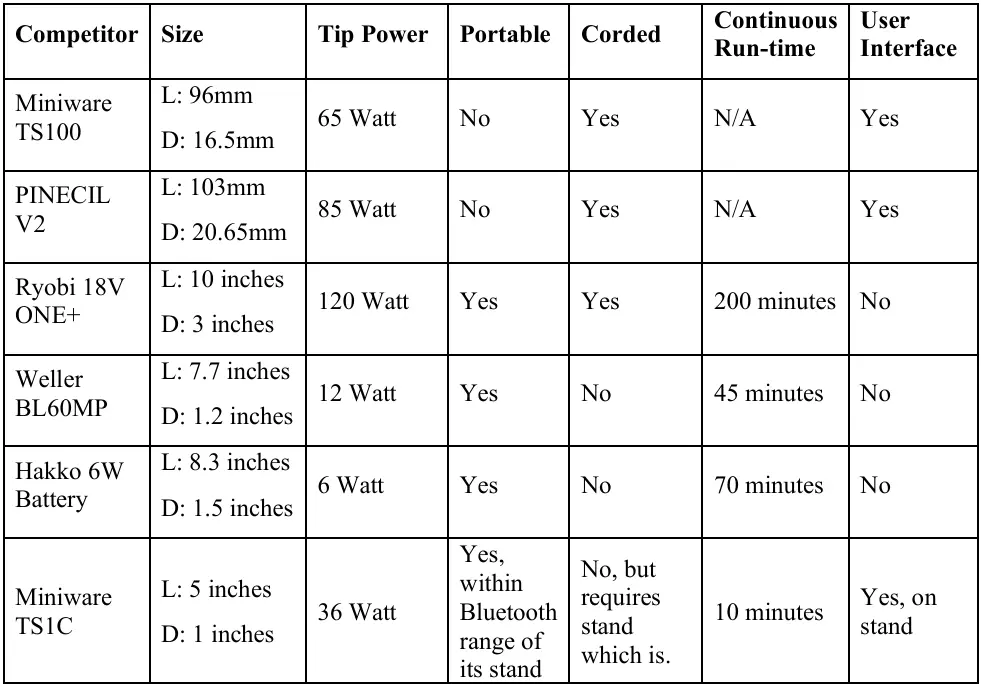

A competitor analysis was conducted across several portable soldering irons to benchmark performance, usability, and portability.

Existing products span a wide range of tradeoffs. Compact irons like the TS100 and Pinecil V2 offer good performance and user interfaces but remain tethered to external power. High-power tools such as the Ryobi 18V ONE+ provide long runtime and high temperatures but are bulky and less nimble. Fully cordless options like the Weller BL60MP and Hakko battery irons improve portability at the cost of power, heat-up speed, or interface quality.

The design goal of this project was to combine the strongest aspects of these products into a single system: true cordless operation, a compact and ergonomic form factor, fast heat-up, a modern user interface, and accessory features such as tip illumination and status indication, without relying on a corded power source during use.